Flat roof options include EPDM, TPO, PVC, and modified bitumen. It’s easy to feel unsure about which one fits best with so many technical details to consider. Whether you’re a homeowner planning repairs or managing a commercial property, knowing what each material offers can save you time, money, and frustration.

This guide covers everything you need to know, including common challenges, performance factors, climate suitability, and real-world comparisons.

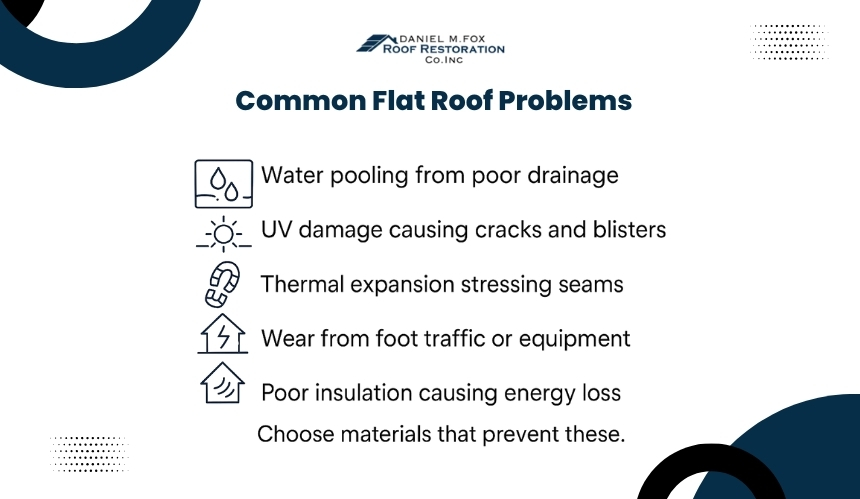

What Problems Do Flat Roofs Commonly Face?

Flat roofs come with unique challenges that make material selection more important than many people realize. The five most common problems in flat roofs are explained below:

- Water Pooling: Because flat roofs have little to no pitch, water can collect after rain or snow. If drainage is poor, this leads to leaks, mold, and structural damage.

- UV and Heat Exposure: Flat roofs get direct sunlight for longer periods. Without UV-resistant materials, the surface can crack, blister, or break down faster.

- Temperature Fluctuations: Extreme heat or cold can cause the roof to expand and contract. Over time, this movement stresses seams, joints, and materials that aren’t flexible.

- Foot Traffic and Equipment Load: HVAC units, solar panels, or simple foot access during maintenance can wear down surfaces that aren’t built to handle it.

- Insulation and Energy Loss: Many older flat roofs lack proper insulation. This raises energy costs and makes it harder to maintain a comfortable indoor temperature.

Understanding these common issues is the first step. In the next section of this article , we’ll look at the roofing materials specifically designed to prevent them.

What Are the Best Materials for a Flat Roof?

Flat roofs are exposed to more environmental stress than pitched ones. They deal with water pooling, direct sunlight, fluctuating temperatures, and foot traffic from maintenance access.

Here’s a breakdown of the best flat roofing materials, including their technical strengths, ideal applications, and potential limitations.

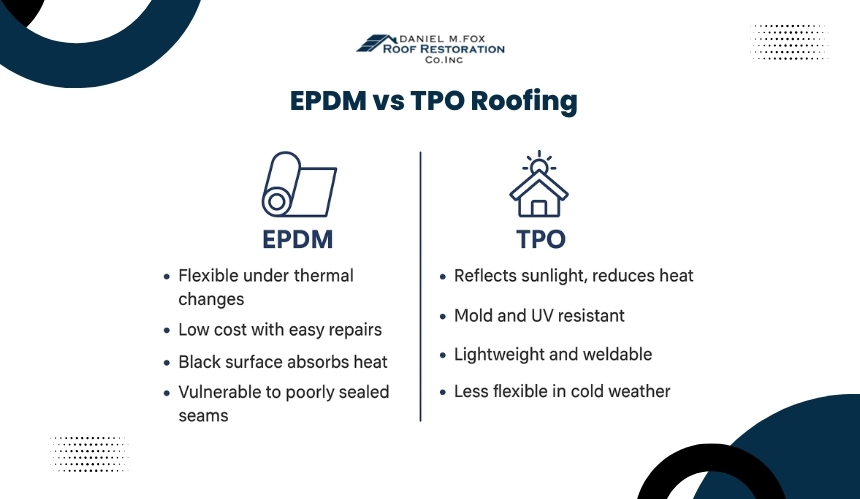

1. EPDM Rubber Roofing

EPDM is a synthetic rubber membrane commonly used for flat and low-slope roofs. It comes in large rolls, which reduces the number of seams, and it’s known for its flexibility under extreme temperature swings.

Its elasticity allows it to handle thermal expansion and contraction without cracking. This makes it a reliable option in areas with significant seasonal temperature changes. EPDM also performs well in regions where snow accumulation or frost cycles are common.

Pros of EPDM Rubber Roofing:

- Flexible and stretchable under thermal stress

- Long-lasting with proper care

- Low material and installation cost

- Simplified repair and patching process

Cons of EPDM Rubber Roofing:

- Black surface absorbs heat unless coated with reflective paint

- Seams can be vulnerable if not sealed well

- Limited visual appeal compared to newer materials

EPDM rubber roofing is best for budget-conscious projects in colder climates, such as residential buildings or small commercial properties. It works well in areas where insulation and movement tolerance are key.

2. TPO (Thermoplastic Polyolefin)

TPO is a white single-ply membrane that reflects sunlight and offers a balance of strength, energy efficiency, and value. It’s typically heat-welded at the seams for strong waterproofing.

Its UV resistance reduces heat absorption, which helps control indoor temperatures during the summer. The smooth surface also resists dirt buildup, making it a cleaner, lower-maintenance option in dusty or industrial zones.

Pros of TPO Roofing:

- High reflectivity reduces cooling costs

- Mold and UV resistant

- Lightweight with strong seam bonding

- Competitive pricing for commercial-scale use

Cons of TPO Roofing:

- Less flexible than rubber membranes in cold weather

- Shorter track record compared to other systems

- Quality can vary across manufacturers

TPO roofing is best for commercial roofs in hot climates, energy-efficient buildings, and properties where appearance and long-term energy savings are important.

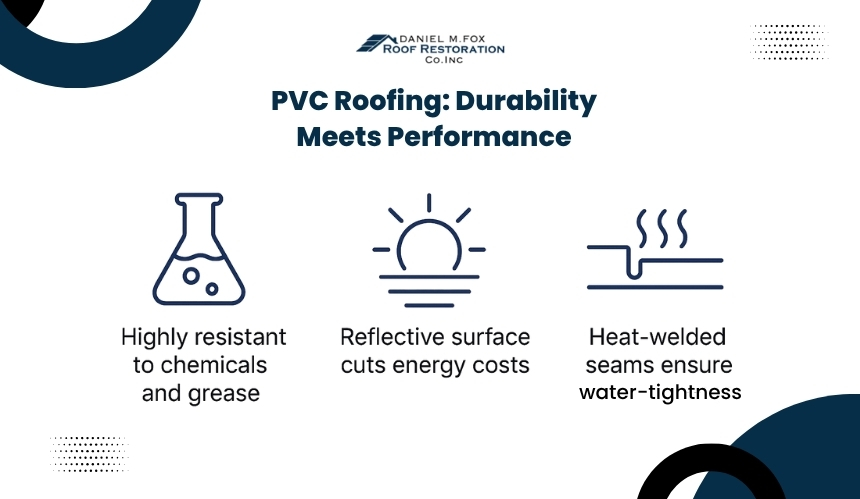

3. PVC (Polyvinyl Chloride) Roofing

PVC is a thermoplastic roofing membrane reinforced with fiberglass or polyester layers. It’s chemically stable and highly resistant to contaminants, oil, and standing water.

Because of its high puncture resistance and rigid structure, PVC is ideal for roofs with foot traffic, such as buildings with rooftop HVAC systems or solar installations.

Pros of PVC Roofing:

- Excellent for areas exposed to chemicals or grease

- Reflective surface helps cut energy costs

- Heat-welded seams create watertight bonds

- Minimal long-term maintenance

Cons of PVC Roofing:

- More expensive upfront than EPDM or TPO

- Can become brittle in extreme cold if not properly reinforced

- Requires skilled labor for installation

PVC roofing works well in industrial buildings, restaurants, labs, or commercial sites with high exposure to foot traffic, heat, or airborne contaminants.

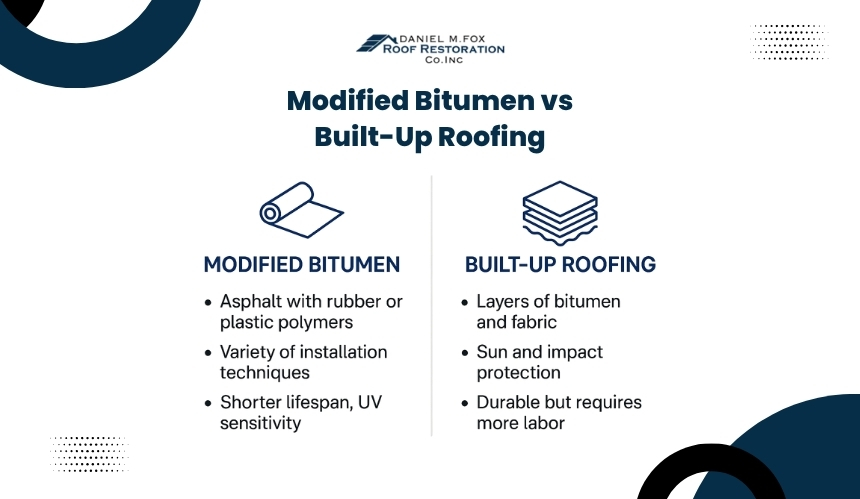

4. Modified Bitumen Roofing

Modified bitumen is an asphalt-based material that includes rubber or plastic polymers for added flexibility. It’s installed in overlapping rolls using heat, adhesives, or peel-and-stick methods.

Its layered construction adds redundancy in waterproofing, which helps where drainage is inconsistent. It’s also more tolerant of foot traffic than some single-ply systems.

Pros of Modified Bitumen Roofing:

- Adaptable to multiple installation methods

- Moderate resistance to wear from maintenance activities

- Relatively low cost with decent performance

- Effective for buildings without precise drainage slopes

Cons of Modified Bitumen Roofing:

- Shorter lifespan than modern membranes

- Labor-intensive installation process

- May blister or crack under intense UV exposure

Modified bitumen roofing is ideal for low-rise buildings, budget-sensitive projects, or roofs that get occasional use but need more than basic coverage.

5. Built-Up Roofing (BUR)

BUR consists of alternating layers of bitumen and fabric, typically finished with gravel or a UV-reflective coating. This multi-ply system has been used for over a century and remains a go-to in heavy-duty flat roofing.

BUR handles water pooling better than many single-ply systems due to its thickness and redundancy. The gravel surface also helps prevent UV degradation and resists physical damage from rooftop equipment or incidental foot traffic.

Pros of Built-Up Roofing:

- Highly waterproof due to a layered system

- Good protection against the sun and impact

- Time-tested reliability in commercial settings

- Effective thermal performance in moderate climates

Cons of Built-Up Roofing:

- Heavy; may require additional structural support

- Slow, labor-intensive installation

- Leaks are harder to detect and fix

Large flat commercial buildings where waterproofing and durability are top priorities, especially where occasional equipment access is needed.

6. Spray-On Roofing (Silicone or Polyurethane Foam)

Spray-on roofing is a liquid foam or coating that expands on application to form a continuous, insulated, and waterproof layer. It bonds directly to the existing roof surface.

This system works especially well for aging roofs or those with uneven surfaces. It fills in dips and cracks, helping correct poor drainage and eliminate ponding water. Its insulation properties also improve indoor temperature stability.

Pros of Spray-On Roofing:

- Seamless and fully adhered coverage

- Strong thermal insulation

- Fast installation over existing roofs

- Adapts to unusual roof shapes and penetrations

Cons of Spray-On Roofing:

- The application is sensitive to weather conditions

- Needs periodic recoating to maintain protection

- Only suitable when installed by trained professionals

Spray-on roofing is best for older buildings needing retrofit solutions, roofs with multiple penetrations or drainage issues, and owners looking for both insulation and waterproofing in one system.

Flat Roof Material Comparison Table: A Quick Summary

Choosing the right flat roof material becomes easier when you compare the key details side by side. Below is a comparison table to help you evaluate each option based on lifespan, average cost, energy efficiency, and ideal use cases.

Material | Avg. Lifespan | Cost per Sq. Ft. (Installed) | Energy Efficiency | Ease of Maintenance | Best For |

EPDM | 20–30 years | $4.00 – $8.00 | Moderate | Easy | Homes or small buildings in cooler climates |

TPO | 15–25 years | $5.00 – $8.50 | High | Low | Energy-conscious buildings in warm climates |

PVC | 20–30 years | $7.00 – $11.00 | High | Very Low | Restaurants, chemical facilities, high-traffic areas |

Modified Bitumen | 10–20 years | $4.50 – $8.00 | Moderate | Moderate | Cost-effective roofs in temperate regions |

Built-Up Roofing (BUR) | 15–25 years | $6.00 – $10.00 | Low to Moderate | Moderate to High | Large flat roofs needing multi-layer protection |

Spray-On Roofing | 20–30 years | $6.00 – $12.00 | Very High | Low | Irregular roof shapes or fast renovations |

How to Use This Table to Choose the Right Flat Roof Material

- If you’re on a tighter budget, EPDM and modified bitumen offer reliable performance with lower upfront costs.

- If energy savings are a priority, TPO and PVC provide strong reflectivity and cooling efficiency.

- If long-term durability matters, spray-on roofing systems and PVC deliver extended lifespan with fewer issues.

- If your roof gets regular foot traffic, PVC offers strong resistance to wear and mechanical stress.

- If your roof has an uneven surface or complex layout, spray-on systems adapt easily and reduce installation hassle.

Frequently Asked Questions

Can I install regular shingles on a flat roof?

No, asphalt or architectural shingles aren’t suitable for flat roofs. They need a steeper slope (at least 3:12 or about 14 degrees) to shed water effectively, so water pooling would compromise their durability and performance.

Can I use my flat roof for a terrace, garden, or solar panel installation?

Yes. Flat roofs offer usable space for terraces, gardens, or solar panels, but that may affect the choice of material and structural support. It’s essential to tell your installer about any future plans so they can recommend materials that handle added weight, foot traffic, and equipment safely.