A Quick Answer: For homes in Newton, MA, both asphalt shingle and rubber roofing offer reliable protection, but the better option depends on the property’s structure, slope, and long-term goals. Asphalt shingles remain the go-to choice for traditional, sloped roofs thanks to their affordability, layered design, and wide aesthetic range. Rubber roofing, often used for flat or low-slope surfaces, provides exceptional waterproofing, energy efficiency, and durability under New England’s fluctuating temperatures. |

Each system brings its own advantages in terms of installation, durability, and upkeep. Selecting the right one depends on structural design, energy goals, and maintenance expectations rather than a single “better” choice.

This article examines both roofing types in context, exploring their build, performance, and long-term value, to guide Newton homeowners toward a roof that matches their property’s specific needs.

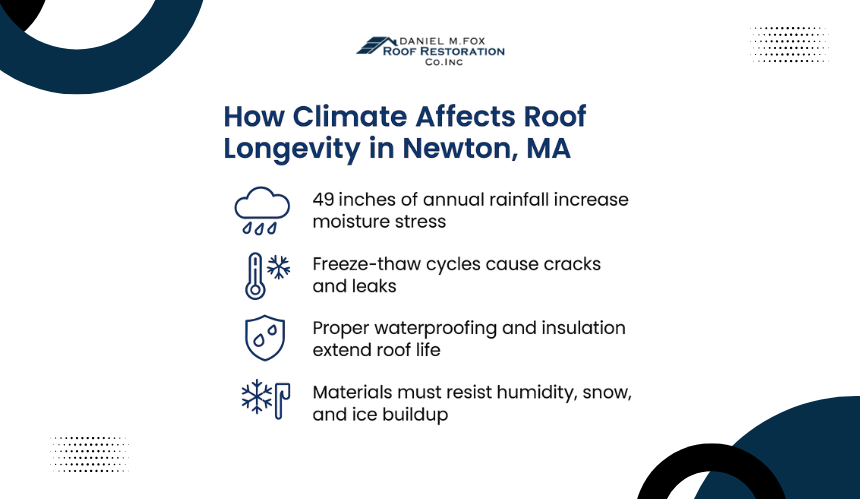

How Does Climate Affect Roof Longevity in Newton, MA?

Homes in Newton, Massachusetts face an average annual rainfall of approximately 49 inches (about 1240 mm). This level of precipitation underscores the importance of selecting roofing materials that can withstand persistent moisture, freeze-thaw cycles, and variable weather patterns.

In this region, effective roofing does more than cover the home: it protects structural elements from moisture intrusion, helps maintain interior temperature stability, and reduces the risk of problems like ice dams and mold.

For a property in Massachusetts, choosing materials with strong waterproofing, adequate insulation support, and resilient attachment systems is essential for long-term performance.

Understanding Asphalt Shingle Roofs

Asphalt shingles are among the most widely used roofing materials in the United States, offering a balance between cost, reliability, and aesthetic appeal.

For homeowners in Newton, MA, they remain a common choice for pitched or gabled roof designs where appearance and practicality intersect. These shingles are built to provide layered protection against the region’s moisture-heavy weather while maintaining a clean, traditional look that complements local architectural styles.

What Are Asphalt Shingles Made Of?

Asphalt shingles consist of multiple layers engineered to resist water, wind, and UV exposure. The base layer is typically a fiberglass mat that provides structural strength, followed by a coating of asphalt that serves as the waterproof barrier. The top surface features mineral granules that shield the roof from sunlight and enhance its appearance.

Common types of Asphalt Shingle include:

- 3-Tab Shingles: Lightweight and affordable, ideal for budget-conscious projects.

- Architectural Shingles: Thicker, dimensional design for added depth and weather protection.

- Luxury Shingles: Premium-grade materials that replicate the look of slate or wood shakes.

How Long Do Asphalt Shingle Roofs Last in Massachusetts?

With proper installation and regular maintenance, asphalt shingle roofs typically last 20 to 30 years in Massachusetts’ climate. However, longevity can vary based on ventilation, slope, and exposure to moisture.

High winds and storms are another key concern in Massachusetts. Quality asphalt shingles are rated to resist winds up to 110–130 mph when properly installed. However, older or poorly fastened shingles can loosen over time, especially on steep pitches.

Ice dams, strong winds, or poor attic insulation can accelerate wear, making periodic inspections by a roof maintenance specialist in Netwon, MA, essential to maintaining their performance.

What Are the Main Advantages of Asphalt Shingle Roofs?

- Affordability: Lower initial costs compared to many other roofing materials.

- Design Versatility: Available in numerous colors and textures to match different home styles.

- Ease of Installation and Repair: Straightforward replacement process minimizes labor time and cost.

- Compatibility: Works effectively with most pitched roof structures found in Newton’s residential neighborhoods.

What Are the Limitations of Asphalt Shingle Roofs Homeowners Should Consider?

While asphalt shingles perform well for many homes, they are less suited to flat or low-slope roofs where standing water can cause damage.

Over time, granule loss and heat absorption may reduce efficiency, especially on roofs with direct sun exposure. In regions with frequent freeze-thaw cycles, like Newton, proper attic ventilation and underlayment installation help prevent premature deterioration.

Consulting an experienced asphalt shingle roofing company in Netwon, MA, can help homeowners assess the structure, strengths, and limitations of asphalt shingle roofing accurately and ensure the right installation methods are applied for longer-lasting performance.

Understanding Rubber Roofing System

Rubber roofing, also known as single-ply membrane roofing, has gained popularity for its strength, energy efficiency, and adaptability in both residential and commercial settings.

For homeowners it is particularly effective on flat or low-slope roofs where water drainage can be a concern. The material’s flexibility and watertight design make it a dependable solution for protecting homes against heavy rainfall and freeze-thaw cycles common in New England.

What Materials Are Used in Rubber Roofing?

Rubber roofing systems are typically made from synthetic materials designed to withstand UV exposure, temperature fluctuations, and water intrusion. The two most common types include:

- EPDM (Ethylene Propylene Diene Monomer): A durable black membrane known for its elasticity, ideal for roofs that expand and contract with seasonal changes.

- TPO (Thermoplastic Polyolefin): A white reflective membrane that helps reduce heat absorption, enhancing energy efficiency in warmer months.

Both materials can be installed using adhesive bonding, mechanical fastening, or heat welding, depending on the roof’s design and slope. Their seamless application reduces the likelihood of leaks and requires minimal maintenance over time.

Is Rubber Roofing Ideal for Newton’s Climate?

Newton’s combination of heavy precipitation and varying temperatures makes rubber roofing a reliable option for long-term weather protection. Its waterproof nature prevents moisture buildup, while its flexible composition minimizes cracking during freeze-thaw cycles.

Rubber roofing adheres directly to the roof deck, creating a sealed surface that minimizes uplift and water penetration during storms. This makes it a reliable option for structures exposed to frequent wind gusts and heavy rainfall.

Homeowners who experience issues with pooling water or recurring leaks often find rubber roofing an effective upgrade from traditional materials.

What Are the Key Advantages of Rubber Roofing Systems?

- Longevity: Can last 40–50 years with proper installation and care.

- Energy Efficiency: Reflective surfaces reduce cooling costs in summer.

- Low Maintenance: Fewer seams mean fewer repair needs over time.

- Sustainability: Many products are recyclable, contributing to eco-friendly building practices.

How Long Does Rubber Roofing Last in Massachusetts?

In Massachusetts’ climate, rubber roofing can last between 40 and 50 years with professional installation and proper upkeep.

EPDM membranes generally last longer due to their resistance to UV degradation and temperature swings, while TPO offers better reflectivity and energy savings.

Regular inspections every few years ensure seams remain sealed and drainage pathways stay clear, extending the system’s overall lifespan.

Are There Any Drawbacks of Rubber Roofing to Consider?

While rubber roofing excels in performance, it has a few limitations. The initial installation cost is higher compared to asphalt shingles, and aesthetic options are more limited.

Its appearance may not blend as easily with traditional roof styles found in Newton’s historic neighborhoods. However, when installed by a skilled rubber roofing contractor in Newton, MA, these systems offer exceptional long-term value and resilience against moisture intrusion.

By understanding how rubber roofing materials perform in local conditions, homeowners can better determine whether this modern, weatherproof option aligns with their property’s structure, energy goals, and desired maintenance level.

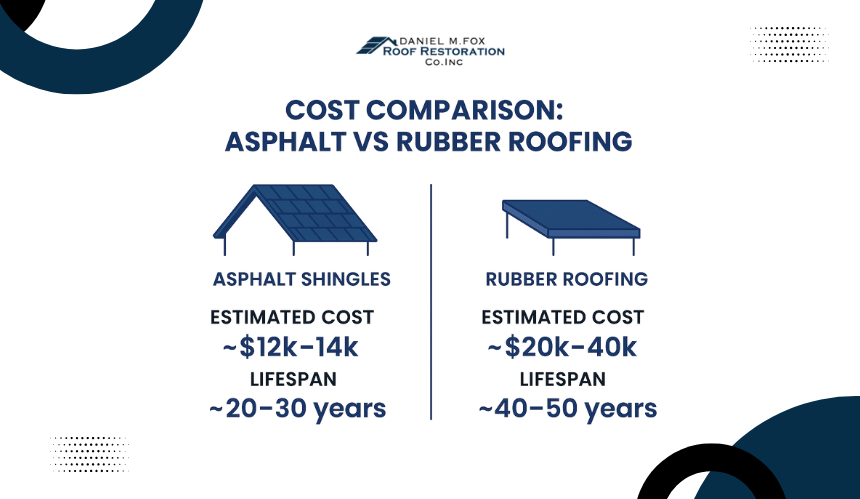

Cost Comparison: Asphalt Shingle vs. Rubber Roofing

Understanding the financial side of a roofing project helps homeowners plan more confidently. Let’s breaks down the actual roofing costs in Massachusetts, including realistic estimates for both asphalt shingle and rubber systems commonly installed in Newton, MA.

Below are authentic, market-based pricing estimates specific to the Newton area:

- For a full roof replacement using asphalt shingles in Massachusetts the average cost is around $7,361, with most projects falling between $5,748 and $17,575.

- Asphalt shingle replacement cost around $6.84 per sq ft (or approximately $13,855 for a 2,025 sq ft roof) based on recent data.

- Rubber roofing membranes (e.g., EPDM or TPO) in Massachusetts, cost roughly $10–$20 per sq ft, depending on slope, condition, and complexity.

Considering a typical Newton home roof of ~2,000 sq ft:

- Asphalt shingles: ~$12,000–$14,000 (on the mid-end)

- Rubber roofing: ~$20,000–$40,000 or more depending on the specification

The higher up-front cost of rubber roofing may be offset by longer service life and better resistance to moisture and freeze-thaw damage.

Additionally, reflective rubber roofing (TPO) may reduce cooling loads in summer, further improving its value in regions with heat waves.

Example Cost Scenarios Between Asphalt Shingle and Rubber Roofing

Roof Type | Estimated Cost | Lifespan Estimate | Notes |

Asphalt Shingle | ~$6–7 per sq ft (~$12k–14k for 2,000 sq ft) | ~20–30 years | Good for pitched roofs, lower initial cost |

Rubber Roofing Membrane | ~$10–20 per sq ft (~$20k–40k for 2,000 sq ft) | ~40–50 years | Best for flat or low-slope roofs, higher cost |

Note: These are estimated for Massachusetts region, actual costs in Newton may vary based on roof complexity, pitch, tear-off requirements, local labor rates, and permit fees.

Key Factors that can Increase the Cost

- Roof size and pitch: Larger or steep-sloped roofs increase labor and materials.

- Material type and quality: Premium shingles or high-performance rubber membranes add to cost.

- Existing roof condition: Removing old layers, repairing decking, or fixing structural issues adds to total.

- Labor and local codes: Newton area labor rates and Massachusetts building code compliance drive costs.

- Timing of installation: Off-peak seasons may offer better pricing; weather delays affect schedule/cost.

Environmental and Energy Efficiency of Asphalt Shingle and Rubber Roofs

Roofing materials play a major role in a home’s overall energy use and environmental footprint. In Newton, MA, where summers can be warm and winters are long, the right roof can improve comfort while reducing energy costs.

Rubber roofing performs well in this regard due to its reflective surface, which helps lower indoor temperatures and enhances cooling efficiency. Its long service life and recyclability also make it one of the more sustainable roofing options available today.

Asphalt shingles have become more energy-efficient with the introduction of cool roof designs and lighter color blends that reflect more sunlight. Though not as recyclable as rubber materials, they remain a cost-effective and increasingly eco-conscious option for homeowners seeking balanced performance and value.

Which Roofing Option Is Right for You: Rubber or Asphalt Shingles?

Choosing between asphalt shingle and rubber roofing depends on your home’s structure, style, and long-term goals. Here’s a quick guide to help you decide:

- Choose asphalt shingle roofing if you want a classic look, lower upfront cost, and a material suited for steep or decorative roof designs. It’s ideal for homeowners prioritizing curb appeal and budget-friendly installation.

- Choose rubber roofing if your home has a flat or low-slope roof and you prefer long-term durability with minimal maintenance. It’s the better option for energy efficiency, waterproofing, and lasting performance in Newton’s variable climate.

Each option serves different needs, so the right choice comes down to whether appearance, cost, or endurance matters most for your property.

Frequently Asked Questions

Can rubber roofing be installed over an existing roof?

Yes, in many cases rubber roofing can be installed over an existing layer if the surface is stable and properly prepared. This approach can reduce labor costs and waste, but a professional inspection is necessary to confirm structural suitability.

What type of maintenance does a rubber roof require?

Rubber roofs need minimal maintenance, typically just annual cleaning and inspection to remove debris, check for seam integrity, and ensure proper drainage. Applying a protective coating every few years can further extend lifespan.

Are asphalt shingles recyclable after replacement?

Some recycling programs now accept used asphalt shingles, converting them into pavement materials or aggregate mixes. Homeowners in Massachusetts can ask local contractors about recycling options when scheduling a replacement.

How does roof color impact indoor temperature in Massachusetts homes?

Light-colored or reflective roofing materials absorb less heat, keeping homes cooler in summer. Darker roofs may improve snow melt in winter but can lead to higher cooling costs during warm months.

Is it possible to combine different roofing materials on the same home?

Yes, mixed-material installations are becoming more common. For example, homeowners may use asphalt shingles on pitched sections for appearance and rubber membranes on flat areas for waterproofing. This hybrid approach can balance aesthetics and function.