When it comes to commercial properties, selecting the right roofing material is crucial for both long-term durability and cost efficiency. One of the top choices for building owners and facility managers is EPDM (Ethylene Propylene Diene Monomer) rubber roofing. EPDM offers exceptional durability, protecting properties from harsh weather conditions, UV rays, and temperature fluctuations.

It is also known for its cost-saving benefits, both in terms of installation and long-term energy savings. Additionally, the installation process for EPDM is straightforward, making it a popular choice for businesses looking to minimize downtime during construction.

In this guide, we’ll explore how EPDM roofing can benefit your commercial property, from its durability to its cost savings and the simple installation process.

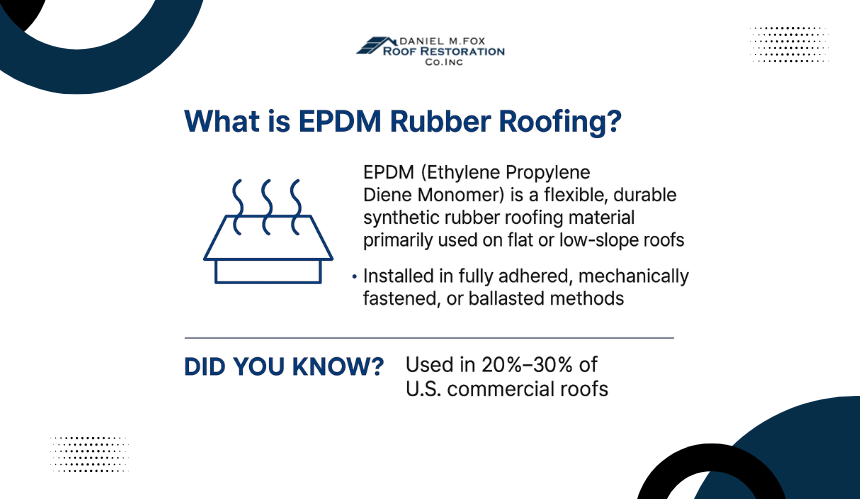

What is EPDM Rubber Roofing?

EPDM (Ethylene Propylene Diene Monomer) is a synthetic rubber roofing material made from a blend of ethylene, propylene, and a small amount of diene. This composition makes it highly flexible, durable, and resistant to a range of environmental factors.

EPDM is primarily used in low-slope and flat roofing applications due to its excellent waterproofing properties. The material is often installed by EPDM roofing experts in one of three ways: fully adhered, mechanically fastened, or ballasted. We will explain all these methods in the next sections of the article.

| Did you know? Approximately 20% to 30% of commercial roofs in the United States use EPDM roofing membranes. This makes it one of the most popular synthetic membranes for commercial and flat roof applications. |

Cost Savings: How EPDM Roofing Helps Cut Long-Term Expenses

One of the major advantages of EPDM roofing for commercial properties is its cost-effectiveness. While the initial installation cost of EPDM may be higher than that of some other roofing materials, the long-term savings make it an attractive option for building owners looking to minimize overall roofing expenses.

Does EPDM Roofing Reduce Maintenance Costs?

First and foremost, EPDM’s durability significantly reduces maintenance and repair costs. Unlike other roofing materials that may require frequent inspections or repairs due to weather damage, EPDM’s ability to withstand extreme conditions means fewer issues over time. This durability translates into fewer unexpected expenses for building owners.

How Does EPDM Roofing Save on Energy Bills?

Additionally, EPDM roofing offers energy savings. Its reflective properties can help reduce cooling costs by keeping buildings cooler during the summer months. In regions where air conditioning costs are high, the energy-efficient nature of EPDM can result in substantial savings year after year.

Can EPDM Roofing Installation Help Save on Labor Costs?

The installation process for EPDM is relatively quick, which can help minimize downtime and reduce labor costs compared to other, more complex roofing systems. When you hire an EPDM roofing installation expert, they ensure that the installation is done efficiently, helping you save money on labor costs and preventing future roofing issues.

In the long run, EPDM roofing is a wise investment that not only protects your building but also contributes to significant cost savings. The combination of reduced maintenance, lower energy bills, and quick installation makes EPDM a financially sound choice for commercial property owners.

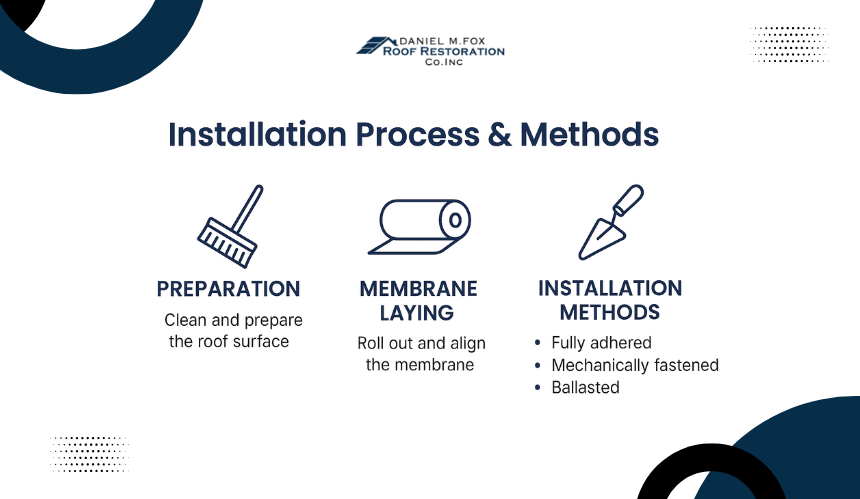

How is EPDM Roofing Installed?: A Step-by-Step Guide

EPDM roofing can be installed in three main ways: fully adhered, mechanically fastened, or ballasted. The choice of method depends on the building’s structure and the specific needs of the property.

- Fully Adhered Installation: In this method, the EPDM membrane is glued directly to the roof deck using a strong adhesive. This is a common method for buildings with smooth, flat surfaces. It provides a secure, seamless roof system with excellent waterproofing properties.

- Mechanically Fastened Installation: This method involves securing the EPDM membrane to the roof deck using fasteners and plates. It is often used for buildings with a more robust structural design or where wind resistance is a concern.

- Ballasted Installation: In this approach, the EPDM membrane is held in place by a layer of gravel or other heavy materials. It is commonly used for low-slope roofs and can be a cost-effective installation option.

What is the EPDM Roofing Installation Process?

- Preparation: The roof surface is thoroughly cleaned and prepped, removing any debris or old roofing materials. This ensures a strong bond between the EPDM membrane and the roof deck.

- Membrane Laying: Once the roof is prepped, the EPDM membrane is rolled out across the surface. The seams are then aligned carefully to ensure a proper fit.

- Seaming and Sealing: For a fully adhered or mechanically fastened system, the seams of the EPDM membrane are sealed to prevent water infiltration. A strong adhesive or seam tape is applied, ensuring that the roof remains watertight.

- Final Inspection: Once the EPDM membrane is in place, the roofing installation expert performs a thorough inspection to ensure that the roof is properly sealed and secured, with no areas left vulnerable to leaks.

Looking for a professional to ensure your EPDM roof is installed correctly? Daniel Fox Roofing Inc. is here for you. Our team has the expertise and the right tools to handle every aspect of the installation, from aligning the membrane to sealing seams and ensuring proper weather resistance. With our help, you’ll avoid costly mistakes and ensure a durable, long-lasting roof.

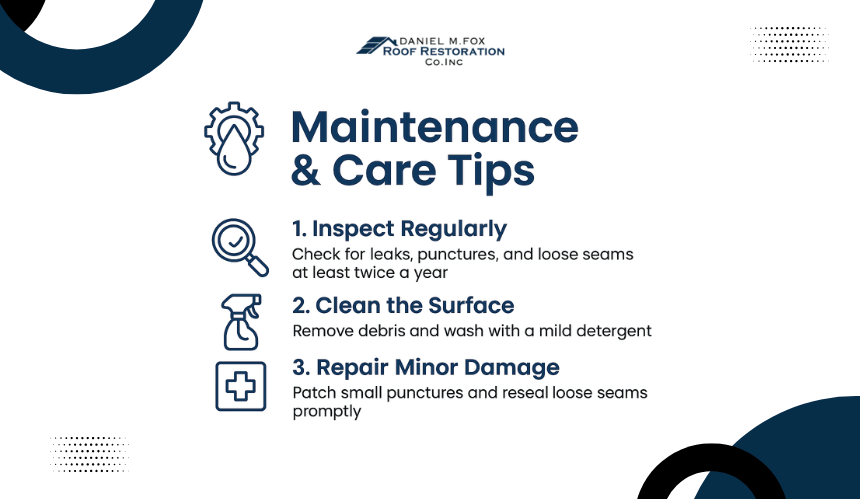

EPDM Roofing Maintenance: Keeping Your Commercial Roof in Top Condition

Maintaining your EPDM roof is essential to extend its lifespan and ensure it continues to provide reliable protection for your commercial property. Regular maintenance not only prevents unexpected repairs but also helps you avoid costly issues down the road. Here’s a guide to keeping your EPDM roofing in optimal condition.

How to Conduct EPDM Roof Inspections

Regular roof inspections are crucial for detecting potential issues before they become major problems. Conduct a visual inspection at least twice a year and after severe weather events. Here’s what to look for:

- Leaks: Inspect the seams and edges of the roof for any signs of water leakage. Small leaks can turn into larger problems if left unchecked, leading to water damage inside your building.

- Punctures or Tears: Check the membrane for punctures or cuts caused by debris, foot traffic, or weather events. Even minor tears can compromise the roof’s waterproofing ability, so addressing them early is key.

- Loose Seams: Over time, the seams of your EPDM roof can loosen or pull apart. Inspect these areas carefully to ensure they remain intact and properly sealed.

How to Clean EPDM Roofs?

Keeping your EPDM roof clean not only helps maintain its appearance but also ensures it performs efficiently. Here are a few simple cleaning tips:

- Remove Debris: Regularly clear leaves, branches, and other debris from the roof’s surface. Debris buildup can trap moisture, leading to algae growth or other issues.

- Wash with Mild Detergent: Use a mild, non-abrasive detergent mixed with water to clean the roof. Avoid harsh chemicals or pressure washing, as these can damage the membrane.

- Inspect Drains and Gutters: Ensure that all roof drains and gutters are free from blockages to allow for proper water drainage. Clogged gutters can cause water to pool on the roof, leading to leaks or damage.

How to Repair Minor EPDM Roof Damage?

While EPDM is durable, occasional repairs may be needed. For minor damage, such as small punctures or holes, repairs can often be completed without replacing the entire section of the roof. Here’s how to handle basic repairs:

- Patch Minor Punctures: Use an EPDM-compatible patch kit to seal small punctures. Clean the area around the puncture, apply the patch, and ensure it adheres securely.

- Seal Loose Seams: If you notice loose seams, reseal them with an EPDM seam tape or adhesive. It’s important to ensure that seams remain watertight to prevent leaks.

- Addressing Surface Damage: For minor abrasions or scratches, EPDM roof coatings can be applied to restore the surface and maintain its waterproof properties.

While basic maintenance can be handled on your own, complex repairs or significant damage should be left to the professionals. If you notice large tears, widespread leaks, or other serious issues, it’s time to consult a trusted EPDM roof repairing expert.

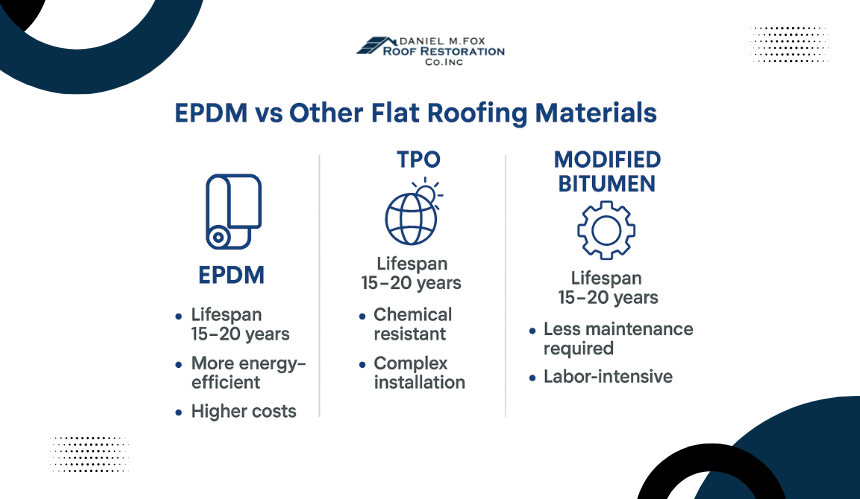

EPDM vs. Other Flat Roofing Materials

When choosing a flat roofing material for your commercial property, it’s important to compare the options available. EPDM stands out due to its durability, cost-effectiveness, and ease of installation, but how does it compare to other popular flat roofing materials like TPO, PVC, and Modified Bitumen?

EPDM vs. TPO

EPDM is known for its durability, lasting 25-30 years with proper maintenance, while TPO has a shorter lifespan of 15-20 years. TPO is more energy-efficient due to its reflective properties, making it ideal for hot climates.

However, EPDM also offers energy savings, especially in colder regions. EPDM is more affordable in both material and installation costs, whereas TPO is more expensive. Installation for EPDM is easier and quicker compared to the more complex TPO installation.

EPDM vs. PVC

EPDM typically lasts 25-30 years, while PVC lasts around 20 years. PVC is resistant to chemicals but can be more expensive and complex to install due to heat-welded seams. EPDM is more cost-effective and easier to install, making it a better long-term investment.

Both materials provide energy savings, but PVC has better reflectivity for cooling costs, while EPDM offers more flexibility in extreme temperatures.

EPDM vs. Modified Bitumen

EPDM lasts 25-30 years, while Modified Bitumen lasts 15-20 years. EPDM is more UV-resistant and requires less maintenance over time. Modified Bitumen is less expensive but needs more upkeep. EPDM also offers better energy efficiency and is easier to install. Modified Bitumen requires more labor-intensive installation processes, increasing costs.

Frequently Asked Questions

How long does an EPDM roof last compared to other roofing materials?

EPDM roofs typically last 25-30 years with proper maintenance, which is significantly longer than other commercial roofing materials like TPO or PVC. Its longevity is due to its ability to withstand extreme weather conditions, UV damage, and thermal expansion without deteriorating. This makes EPDM an excellent investment for long-term roofing protection.

Can EPDM roofing be installed over existing roofing materials?

Yes, EPDM roofing can be installed over an existing roof in many cases, especially when the current roof is in good condition. This method, known as a “retrofit,” saves on the costs and time involved in removing old roofing.

However, proper inspection is necessary to ensure the underlying roof does not have structural issues that could affect the EPDM’s performance.

What is the best time of year to install EPDM roofing?

The best time to install EPDM roofing is during moderate weather, typically in the spring or fall. This is because extreme heat or cold can affect the adhesion of the EPDM membrane. Installing in milder temperatures ensures a secure, long-lasting bond.

However, EPDM can also be installed during winter months, as long as proper precautions are taken to ensure the surface temperature remains above freezing.

Can EPDM roofing withstand extreme weather conditions like hurricanes or heavy snowfall?

EPDM is highly resistant to extreme weather, including heavy snow, intense heat, and even hurricanes. Its flexibility allows it to expand and contract without cracking or losing its waterproofing properties.

In regions prone to high winds or heavy snow, EPDM’s ability to remain intact under pressure makes it an ideal choice for commercial properties seeking durable, weather-resistant roofing.

What are the most common causes of EPDM roofing failure, and how can they be avoided?

The most common causes of EPDM roofing failure include poor installation, lack of proper maintenance, and physical damage from debris or extreme weather.

To avoid these issues, ensure you hire a professional EPDM roofing installation expert, conduct regular inspections, and keep the roof clean and free of debris. Proper care and timely repairs can significantly extend the life of your EPDM roof and prevent costly failures.